1. Material Fundamentals and Microstructural Features of Alumina Ceramics

1.1 Composition, Pureness Qualities, and Crystallographic Residence

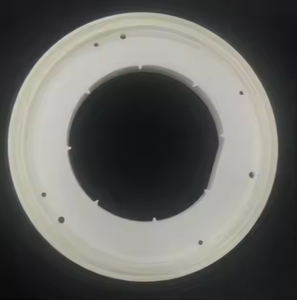

(Alumina Ceramic Wear Liners)

Alumina (Al Two O FIVE), or aluminum oxide, is among the most widely made use of technical porcelains in industrial engineering because of its outstanding balance of mechanical toughness, chemical security, and cost-effectiveness.

When engineered into wear liners, alumina ceramics are typically fabricated with purity levels varying from 85% to 99.9%, with higher purity corresponding to enhanced solidity, use resistance, and thermal efficiency.

The dominant crystalline stage is alpha-alumina, which embraces a hexagonal close-packed (HCP) structure characterized by solid ionic and covalent bonding, contributing to its high melting factor (~ 2072 ° C )and low thermal conductivity.

Microstructurally, alumina ceramics consist of fine, equiaxed grains whose dimension and circulation are managed during sintering to optimize mechanical residential or commercial properties.

Grain dimensions normally range from submicron to a number of micrometers, with finer grains usually improving crack sturdiness and resistance to break propagation under unpleasant loading.

Small additives such as magnesium oxide (MgO) are commonly presented in trace amounts to inhibit unusual grain development throughout high-temperature sintering, ensuring consistent microstructure and dimensional security.

The resulting product shows a Vickers hardness of 1500– 2000 HV, considerably exceeding that of solidified steel (commonly 600– 800 HV), making it extremely resistant to surface area degradation in high-wear atmospheres.

1.2 Mechanical and Thermal Performance in Industrial Issues

Alumina ceramic wear linings are selected largely for their superior resistance to unpleasant, abrasive, and sliding wear mechanisms common in bulk product managing systems.

They have high compressive strength (as much as 3000 MPa), good flexural toughness (300– 500 MPa), and excellent stiffness (Young’s modulus of ~ 380 GPa), enabling them to hold up against intense mechanical loading without plastic deformation.

Although naturally fragile contrasted to steels, their reduced coefficient of rubbing and high surface solidity lessen bit bond and reduce wear rates by orders of magnitude relative to steel or polymer-based options.

Thermally, alumina maintains architectural stability approximately 1600 ° C in oxidizing atmospheres, allowing usage in high-temperature processing environments such as kiln feed systems, boiler ducting, and pyroprocessing devices.

( Alumina Ceramic Wear Liners)

Its low thermal expansion coefficient (~ 8 × 10 ⁻⁶/ K) adds to dimensional stability during thermal cycling, minimizing the risk of breaking as a result of thermal shock when properly set up.

Furthermore, alumina is electrically shielding and chemically inert to many acids, alkalis, and solvents, making it appropriate for harsh settings where metallic linings would deteriorate swiftly.

These mixed homes make alumina porcelains excellent for securing important infrastructure in mining, power generation, cement production, and chemical processing industries.

2. Manufacturing Processes and Design Combination Strategies

2.1 Shaping, Sintering, and Quality Control Protocols

The manufacturing of alumina ceramic wear liners involves a sequence of accuracy manufacturing steps developed to achieve high thickness, very little porosity, and regular mechanical performance.

Raw alumina powders are processed via milling, granulation, and creating strategies such as completely dry pressing, isostatic pushing, or extrusion, relying on the preferred geometry– floor tiles, plates, pipelines, or custom-shaped sectors.

Environment-friendly bodies are after that sintered at temperatures between 1500 ° C and 1700 ° C in air, promoting densification with solid-state diffusion and accomplishing loved one densities surpassing 95%, typically coming close to 99% of theoretical density.

Complete densification is important, as recurring porosity acts as stress concentrators and increases wear and fracture under solution problems.

Post-sintering operations may include diamond grinding or lapping to accomplish tight dimensional tolerances and smooth surface coatings that reduce friction and bit capturing.

Each set undertakes rigorous quality assurance, consisting of X-ray diffraction (XRD) for phase analysis, scanning electron microscopy (SEM) for microstructural examination, and hardness and bend screening to validate compliance with worldwide criteria such as ISO 6474 or ASTM B407.

2.2 Installing Strategies and System Compatibility Factors To Consider

Effective integration of alumina wear linings into commercial devices calls for cautious interest to mechanical accessory and thermal development compatibility.

Typical installment approaches include glue bonding making use of high-strength ceramic epoxies, mechanical attaching with studs or anchors, and embedding within castable refractory matrices.

Glue bonding is commonly made use of for level or gently curved surfaces, offering consistent stress and anxiety circulation and resonance damping, while stud-mounted systems allow for simple replacement and are preferred in high-impact areas.

To fit differential thermal development between alumina and metallic substratums (e.g., carbon steel), engineered gaps, flexible adhesives, or certified underlayers are included to avoid delamination or cracking during thermal transients.

Developers have to additionally think about edge protection, as ceramic floor tiles are prone to breaking at revealed corners; options consist of diagonal sides, steel shadows, or overlapping tile setups.

Appropriate installation makes sure long life span and takes full advantage of the protective function of the liner system.

3. Put On Systems and Efficiency Analysis in Solution Environments

3.1 Resistance to Abrasive, Erosive, and Influence Loading

Alumina ceramic wear linings master settings controlled by three primary wear mechanisms: two-body abrasion, three-body abrasion, and fragment erosion.

In two-body abrasion, hard particles or surfaces straight gouge the liner surface, a typical incident in chutes, hoppers, and conveyor shifts.

Three-body abrasion entails loosened bits entraped in between the lining and moving product, leading to rolling and scraping action that gradually eliminates product.

Erosive wear takes place when high-velocity fragments impinge on the surface area, particularly in pneumatic communicating lines and cyclone separators.

Because of its high hardness and low crack sturdiness, alumina is most reliable in low-impact, high-abrasion scenarios.

It carries out exceptionally well versus siliceous ores, coal, fly ash, and concrete clinker, where wear prices can be minimized by 10– 50 times compared to moderate steel linings.

Nonetheless, in applications involving repeated high-energy influence, such as primary crusher chambers, crossbreed systems incorporating alumina tiles with elastomeric supports or metal guards are commonly utilized to absorb shock and stop crack.

3.2 Area Testing, Life Process Evaluation, and Failing Mode Evaluation

Efficiency evaluation of alumina wear linings includes both laboratory testing and field surveillance.

Standardized examinations such as the ASTM G65 dry sand rubber wheel abrasion test give relative wear indices, while tailored slurry erosion gears mimic site-specific problems.

In commercial settings, wear rate is typically measured in mm/year or g/kWh, with life span projections based on initial density and observed degradation.

Failing settings include surface sprucing up, micro-cracking, spalling at edges, and full ceramic tile dislodgement due to sticky deterioration or mechanical overload.

Root cause evaluation frequently reveals setup mistakes, incorrect quality choice, or unanticipated impact loads as primary factors to premature failure.

Life process cost analysis continually demonstrates that regardless of greater preliminary prices, alumina liners offer remarkable complete price of possession due to prolonged replacement intervals, reduced downtime, and lower maintenance labor.

4. Industrial Applications and Future Technological Advancements

4.1 Sector-Specific Implementations Across Heavy Industries

Alumina ceramic wear liners are released throughout a wide range of industrial sectors where material deterioration poses functional and economic difficulties.

In mining and mineral handling, they secure transfer chutes, mill liners, hydrocyclones, and slurry pumps from rough slurries consisting of quartz, hematite, and other hard minerals.

In nuclear power plant, alumina ceramic tiles line coal pulverizer ducts, boiler ash receptacles, and electrostatic precipitator elements subjected to fly ash disintegration.

Concrete manufacturers make use of alumina linings in raw mills, kiln inlet zones, and clinker conveyors to combat the very abrasive nature of cementitious materials.

The steel market employs them in blast heater feed systems and ladle shadows, where resistance to both abrasion and moderate thermal tons is essential.

Also in much less conventional applications such as waste-to-energy plants and biomass handling systems, alumina ceramics give resilient defense versus chemically hostile and coarse products.

4.2 Emerging Trends: Composite Systems, Smart Liners, and Sustainability

Current study focuses on improving the strength and performance of alumina wear systems with composite layout.

Alumina-zirconia (Al ₂ O THREE-ZrO TWO) compounds utilize transformation toughening from zirconia to boost fracture resistance, while alumina-titanium carbide (Al ₂ O TWO-TiC) qualities offer boosted efficiency in high-temperature moving wear.

Another technology includes installing sensing units within or underneath ceramic linings to keep an eye on wear development, temperature level, and effect frequency– allowing predictive upkeep and digital double combination.

From a sustainability point of view, the extensive life span of alumina liners decreases product usage and waste generation, aligning with circular economic situation concepts in industrial operations.

Recycling of invested ceramic liners right into refractory accumulations or building and construction materials is additionally being explored to reduce ecological impact.

In conclusion, alumina ceramic wear linings represent a foundation of modern commercial wear security technology.

Their outstanding firmness, thermal stability, and chemical inertness, combined with fully grown production and installment practices, make them indispensable in combating product destruction across heavy sectors.

As material scientific research breakthroughs and digital surveillance becomes more incorporated, the next generation of clever, resilient alumina-based systems will further enhance operational effectiveness and sustainability in abrasive environments.

Vendor

Alumina Technology Co., Ltd focus on the research and development, production and sales of aluminum oxide powder, aluminum oxide products, aluminum oxide crucible, etc., serving the electronics, ceramics, chemical and other industries. Since its establishment in 2005, the company has been committed to providing customers with the best products and services. If you are looking for high quality high purity alumina, please feel free to contact us. (nanotrun@yahoo.com)

Tags: Alumina Ceramic Wear Liners, Alumina Ceramics, alumina

All articles and pictures are from the Internet. If there are any copyright issues, please contact us in time to delete.

Inquiry us